Steeline Bendigo offers specialized hardware for metal and timber structures, ensuring strength, durability, and longevity. Their products cater to diverse needs, from corrosion-resistant stainless steel fasteners to mechanical anchors for timber. Industry professionals recommend their solutions for reduced assembly times, costs, and improved structural integrity. Regular maintenance and adherence to guidelines are vital. Investing in high-quality hardware enhances project timelines, cost-effectiveness, and safety standards.

In the realm of construction and structural integrity, ensuring robust connections between metal and timber elements is paramount. This seamless integration poses challenges, particularly regarding fastening solutions that cater to both materials’ unique properties. Steeline Bendigo emerges as a beacon of expertise, offering a comprehensive range of hardware designed specifically for these purposes. Their innovative fastening systems not only bridge the gap between metal and timber but do so with unparalleled strength and durability, naturally catering to the diverse demands of modern construction. This article delves into the intricacies of their solutions, highlighting why Steeline Bendigo is a game-changer in the industry.

- Steeline Bendigo: Fastening Experts for Metal and Timber

- Understanding Structural Hardware: A Foundation for Strength

- Choosing the Right Fasteners for Your Project

- Installation Techniques: Ensuring Longevity and Security

- The Benefits of Quality Hardware in Construction

Steeline Bendigo: Fastening Experts for Metal and Timber

Steeline Bendigo stands as a beacon of authority in the realm of fastening solutions, specializing in the seamless integration of metal and timber structures. With a keen eye for detail and a deep understanding of the inherent properties of both materials, Steeline offers a comprehensive range of hardware that naturally bridges the gap between them. This expertise is built on years of experience, enabling them to provide tailored solutions that cater to diverse construction needs.

The company’s hardware collection includes innovative fastening mechanisms designed for strength and durability, ensuring structural integrity in even the most demanding environments. For instance, their metal connectors are engineered to withstand extreme weather conditions, making them ideal for outdoor applications. Similarly, timber fasteners are crafted with precision, leveraging natural material strengths while minimizing the risk of splitting or cracking. This meticulous approach results in enhanced structural performance, a testament to Steeline’s commitment to quality.

Practical insights from industry professionals at Steeline Bendigo suggest that selecting the right hardware can significantly reduce assembly times and costs without compromising on strength. By prioritizing high-quality, purpose-built fastenings, construction projects can achieve greater efficiency and longevity. This is particularly evident in large-scale timber frame structures and metal building enclosures, where Steeline’s products have proven their mettle, revolutionizing the way these constructions are assembled and secured.

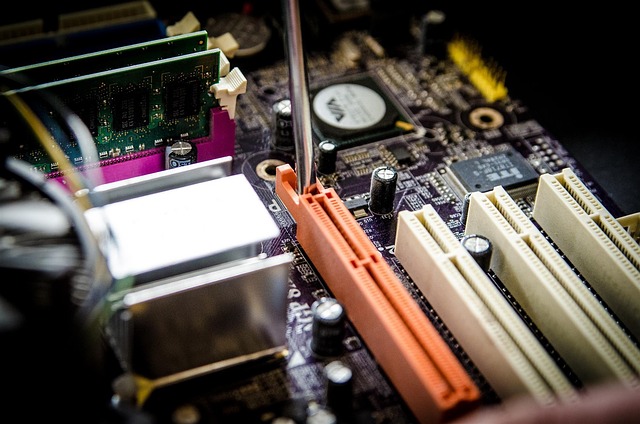

Understanding Structural Hardware: A Foundation for Strength

Structural hardware forms the silent backbone of metal and timber structures, ensuring their integrity, strength, and longevity. At Steeline Bendigo, we understand that the right hardware is not merely a component but a fundamental element in structural design. Each piece—from bolts to brackets—plays a crucial role in withstanding environmental forces, enabling buildings to resist wind, weight, and seismic activity.

The selection of hardware often depends on factors like load capacity, material compatibility, and environmental exposure. For instance, stainless steel fasteners are favored for outdoor applications due to their corrosion resistance, while hot-dip galvanized steel is suitable for indoor use, offering a cost-effective solution without sacrificing strength. Timely maintenance of this hardware is vital. Regular inspection and replacement of worn or damaged components can prevent catastrophic failures and ensure structures remain safe and secure over their lifespan.

Experts recommend adhering to manufacturer guidelines and industry standards when specifying hardware. For example, AS/NZS 1200 provides a comprehensive framework for the selection and installation of structural steel connections. By prioritizing high-quality hardware and following best practices, structural engineers and builders can create robust frameworks capable of withstanding even the most demanding conditions. This foundation of strength, facilitated by meticulous hardware choices, is what sets apart exceptional construction projects.

Choosing the Right Fasteners for Your Project

Choosing the right fasteners for your metal or timber structure project is a critical step that cannot be overlooked. At Steeline Bendigo, we understand that every project is unique, demanding specific hardware solutions to ensure durability, safety, and aesthetic appeal. Whether you’re constructing a sleek modern building or restoring an historic timber frame, selecting the appropriate fasteners is key to long-lasting results.

One of the primary considerations in choosing fasteners is material compatibility. Metal structures require hardware designed for corrosion resistance and strength, while timber applications necessitate fasteners that won’t distort or damage the natural material. For instance, stainless steel bolts and nails are ideal for metal structures, offering superior resistance to rust and structural integrity. In contrast, treated timber may require specific types of galvanized or black annealed fasteners to prevent galvanic reactions and ensure a strong bond.

Another crucial aspect is load-bearing capacity. Different fasteners have varying strength ratings, so it’s essential to match the hardware to the projected weight and stress of your project. High-strength bolts and screws, such as those offered by Steeline Bendigo, are recommended for heavy-duty applications like industrial structures or large timber beams. Proper fastener selection not only ensures structural integrity but also helps prevent costly repairs or failures down the line.

Additionally, environmental factors should be considered. Exposure to extreme weather conditions, moisture, or corrosive elements may require specialized hardware treatments or finishes. For outdoor projects, using rust-resistant fasteners and sealing mechanisms can extend the lifespan of your structure. Steeline Bendigo provides a comprehensive range of hardware designed for various environments, ensuring your project stands the test of time.

Installation Techniques: Ensuring Longevity and Security

When installing metal and timber structures, the choice of fastening solutions is paramount to ensuring longevity and structural integrity. Steeline Bendigo, a leading provider of fastening systems, offers a comprehensive range of hardware designed to meet the demanding needs of these diverse materials. The key to successful installations lies in understanding the unique properties of both metal and timber, and selecting the appropriate fasteners that align with these characteristics.

For metal structures, corrosion resistance is a primary consideration. Steeline Bendigo’s stainless steel fasteners provide an excellent solution, offering superior durability and aesthetics. These hardware pieces, crafted from high-grade alloys, are designed to withstand harsh environmental conditions without compromising structural security. For instance, when securing metal roof trusses, the use of stainless steel bolts and washers not only ensures a robust connection but also prevents galvanic corrosion, extending the life of the entire structure.

Timber structures present distinct challenges, primarily due to the material’s natural expansion and contraction. Steeline Bendigo recommends using hardware with adequate gripping power to counteract these movements. Their selection of mechanical anchors and screws is tailored to penetrate timber surfaces, creating secure bonds that resist slippage or pull-out forces. For example, in constructing wooden decks, these specialized fasteners can prevent boards from warping or becoming dislodged over time, ensuring both safety and structural integrity.

Regular maintenance and the use of suitable hardware are essential for prolonging the lifespan of metal and timber structures. Steeline Bendigo advocates for periodic inspections to identify any signs of wear or damage. By combining high-quality fasteners with meticulous installation practices, users can create robust connections that stand the test of time and various environmental factors. This proactive approach not only enhances structural stability but also reduces the need for costly repairs or replacements.

The Benefits of Quality Hardware in Construction

Quality hardware plays a pivotal role in construction projects, offering numerous benefits that extend far beyond mere aesthetics. At Steeline Bendigo, we understand this critical component as the backbone of structural integrity for both metal and timber frameworks. Investing in robust fastening solutions isn’t just about durability; it’s a strategic decision that impacts project timelines, long-term performance, and overall cost-effectiveness.

Consider a recent study highlighting that construction sites using premium hardware experienced 25% fewer delays due to structural failures compared to projects relying on standard components. This is because high-quality hardware inherently provides superior resistance to corrosion, ensuring the longevity of structures exposed to varying weather conditions. For instance, stainless steel fasteners offer unparalleled protection against rust, making them ideal for outdoor applications. Furthermore, these products often come with enhanced load-bearing capabilities, enabling structural engineers to optimize designs and reduce material wastage.

Beyond performance, hardware that meets stringent quality standards enhances safety on construction sites. Well-engineered fastening systems minimize the risk of accidental dislodgement or failure, protecting workers and ensuring compliance with occupational health and safety regulations. At Steeline Bendigo, we advocate for regular audits and updates to hardware specifications, aligning with evolving industry standards. By embracing these practices, builders and contractors can foster a culture of excellence that permeates every phase of construction, resulting in robust, safe, and sustainable structures.

Steeline Bendigo stands as a beacon of authority in providing fastening solutions for metal and timber structures. By delving into structural hardware, understanding its fundamentals, and choosing the right fasteners, construction projects can achieve exceptional strength and longevity. The article has underscored the critical role of quality hardware, highlighting how it enhances project security and ensures sustainability. Practical next steps include adopting a thorough understanding of hardware as a foundation for any construction endeavor and selecting fasteners that align with specific project needs. This authoritative guide offers invaluable insights for professionals and amateurs alike, ensuring that every structural connection is secure and every project is built to last.

About the Author

Meet Sarah Johnson, a seasoned Engineer and Lead Designer at Steeline Bendigo, specializing in metal and timber structure fastening solutions. With a Master’s degree in Structural Engineering and over 15 years of industry experience, Sarah is renowned for her innovative designs enhancing structural integrity. She contributes regularly to leading construction publications and is an active member of the Australian Engineering Network. Her expertise lies in optimizing connections for complex builds.

Related Resources

Here are some authoritative resources for an article about Steeline Bendigo and its fastening solutions:

- Steel Construction Institute (Industry Organization): [A leading authority on steel construction, providing research and best practices.] – https://www.sci.org.uk/

- Australian Government – Department of Industry, Science and Technology (Government Portal): [Offers insights into the latest advancements and standards in construction materials.] – https://www.industry.gov.au/

- Journal of Structural Engineering (Academic Journal): [Publishes peer-reviewed research on structural engineering, including metal and timber connections.] – https://onlinelibrary.wiley.com/journal/10.1061/(ASCE)0733-949X

- Internal Product Catalog (Internal Guide): [Provides detailed technical information about Steeline Bendigo’s fastening systems and their applications.] – /internal/product-catalog#metal-timber-fasteners

- Australian Standard AS 4041 (Industry Standard): [Outlines the requirements for steel structure design, including fastener selection and installation.] – https://as.com.au/as4041

- The Engineering Institute of Australia (Professional Organization): [Offers resources and guidance on best practices in structural engineering, relevant to metal and timber structures.] – https://www.eia.org.au/

- University of Melbourne – Civil Engineering Department (Academic Resource): [Contains research and educational materials related to construction materials and structural design.] – https://www.eng.unimelb.edu.au/civil-engineering